Want to quickly reduce cleaning time and ultimately reduce downtime? In this recent project at Unibio’s production site, NNE’s Manufacturing Intelligence consultants quickly installed sensors and location tracking technology to a mobile CIP (Clean in Place) station. The smart solution reduces monitoring procedures and increases the effectiveness of quality management systems.

Customer challenge

CIP (Clean in Place) equipment is designed for cleaning facilities, units, and pipelines on production lines. Unibio was using a mobile CIP station, but unfortunately it didn’t collect data. A lack of data means a lack of insight – so the Unibio team were missing out on potential savings and optimizations.

Our solution

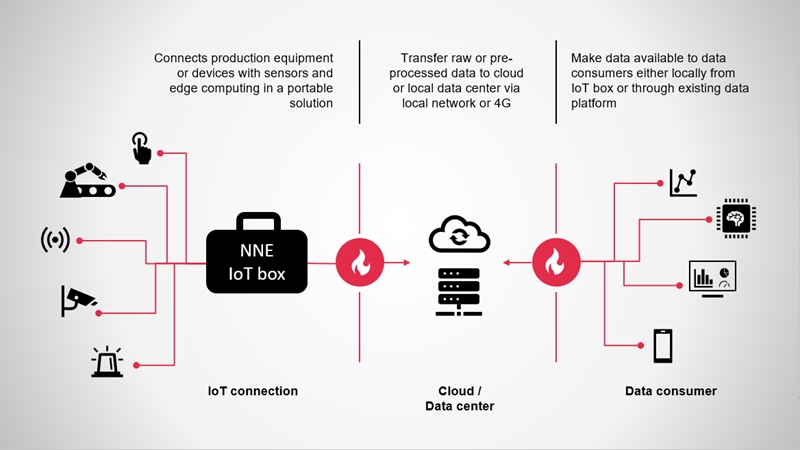

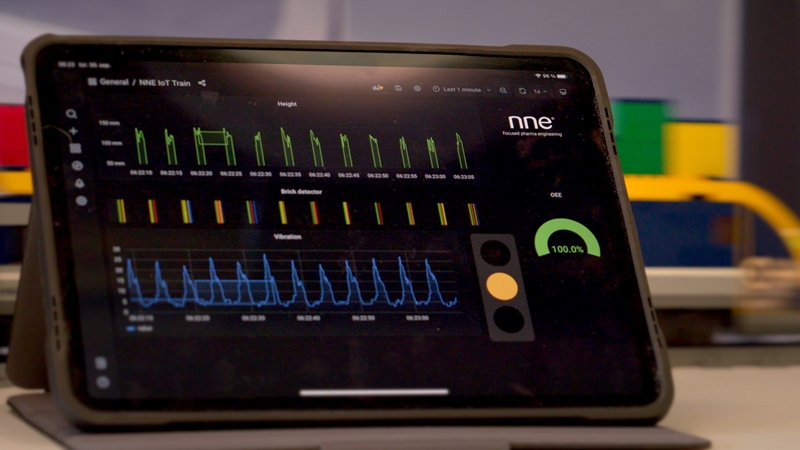

To solve this, NNE added wireless sensors to the mobile CIP station which stream data to the NNE IoT box. The IoT box then transmits the data to the local PI data historian for further analysis. This simple addition means the CIP stations now produce valuable data about a specific CIP procedure on a specific production unit.

In addition, our consultants added location tracking technology (that acts as a local, indoor GPS system) to track each CIP station and where they are in relation to tanks. It also shows which process units are being cleaned in real-time.

Our manually controlled test area consists of satellite units that are moved around to fit each test setup. Our cleaning equipment must match this flexibility, thus making traditional data collection difficult. NNE suggested implementing a wireless data transfer system to counter this problem. The combination of the wireless data transfer and the position system enables us to monitor our cleaning procedures more closely than before. The wireless data transfer system has been a real eye-opener and we are already looking into implementing the system on more of our satellite units.

Wireless data collection coupled with location contextualisation will help reduce cleaning time and thus reduce downtime - ultimately increasing productivity. An added benefit is that, once installed, this real-time location data system can be used to track a wealth of objects within the pharma manufacturing process with a huge amount of potential for future optimizations, such as tracking the operator path.

Fact box

Customer

Unibio

Location

Denmark

Services

Manufacturing Intelligence, digitalization

Technology

Data collection and analysis

Duration

6 weeks

Project completion

2021

Total investment cost

DKK ~ 200,000