Our customer needs to massively increase capacity by 2023 with a flexible, optimizable greenfield pharma manufacturing facility for the future. To deliver, NNE conducted a four-week design sprint to build an innovation and idea catalogue that offers four feasible prototypes to increase capacity at speed and challenge the status quo.

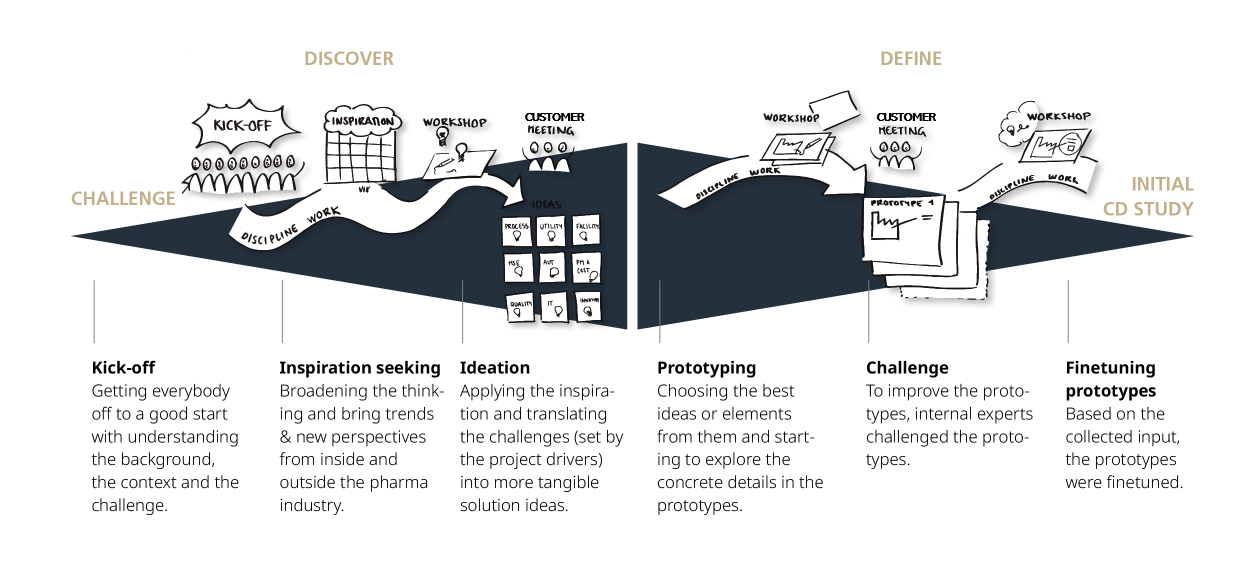

Using the double diamond approach for high-speed innovation

Three parallel teams worked on the prototypes from both Denmark and India. The core goal was to deliver high levels of innovation and generate value in a short period of time. Therefore, the working process utilised the double diamond approach (discover, define, develop, deliver) from design theory.

The double diamond method offers structure and direction, quickly moving a freethinking brainstorm with inspiration from other industries to a workable solution. This helped to generate new ideas while challenging typical solutions to make the facility more efficient.

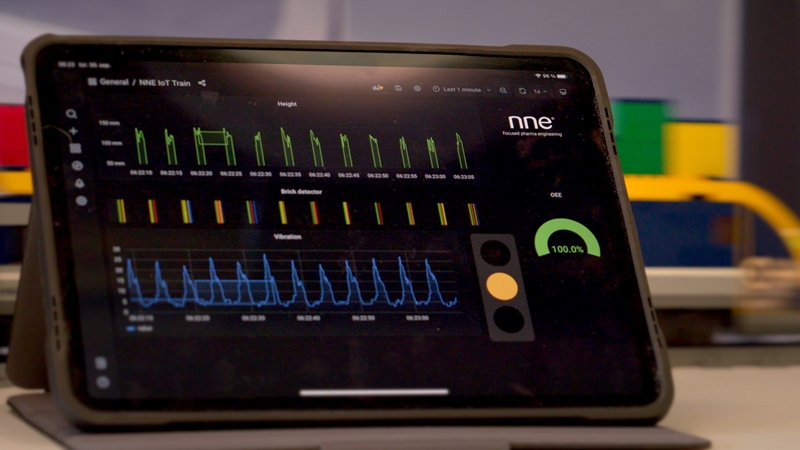

Visualization as a key for collaboration

All inspiration, ideas and prototypes were illustrated and shared with the project team either online or placed visibly in the project space. This allowed everyone to follow progress and build on or challenge ideas.

The final innovation catalogue offered four distinct prototypes with a wide variety of designs ideas, efficiency solutions and possibilities for future adaptation and expansion. Due to its success, NNE was also offered the conceptual design, delivered using the same approach over a period of 8 weeks.

Quick facts

Customer

Confidential

Country

Europe

Project duration

4 weeks for innovation catalogue and 8 weeks for CD

Services provided

Decision design, conceptual design