Developing robust statistical process control (SPC) can do wonders for your quality control. But where do you begin when outlining this strategy? The pilot, of course. And that happens to be the most critical step.

Statistical process control is a great business strategy to consider if your company is experiencing one or more of the following issues:

- Variation in yield or product quality

- Random component errors

- Verifying effect of error correction

- Anchoring optimization projects

- Meeting recent regulatory requirements regarding process verification

Where to begin?

The foolish man built his house on sand and the wise man on rock. The same goes for SPC – the success is in its foundation, or rather, a successful pilot.

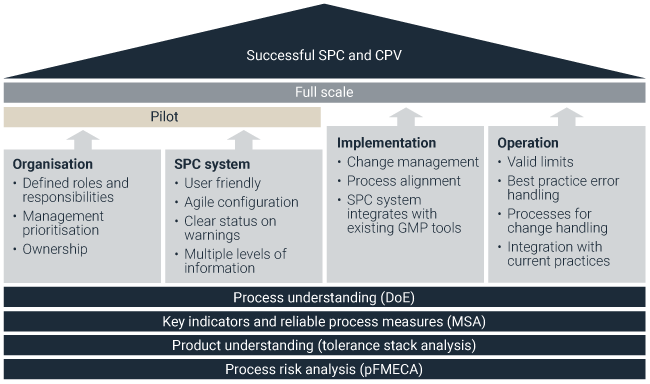

Every company is different and thus, results differ as well. However, the basic steps to achieve a strong control strategy are the same. Manufacturers must begin with a pilot project focused on developing and customizing an SPC system that corresponds to a company's specific processes. Additionally, manufacturers would do well to prepare the entire organization by creating awareness and defining new roles and responsibilities so everyone can embrace the change.

The ability to react flexibly is crucial in the initial phases of preparing for statistical process control implementation.

A journey founded on science

Successful SPC implementation requires more than just software installation. It is a journey founded on science and risk-based analysis. You need to identify critical aspects of the process, establish reliable process measures and indicators and determine the relationship between a healthy process and products.

Agility – the key ingredient

Finally, the ability to react flexibly is crucial in the initial phases of preparing for statistical process control implementation. This is true not only in regards to the system, but also the involved organization. Working with control charts requires a change in approach - from being reactive, to being proactive.

Therefore, it is important to have an engaged group that can adapt as the project evolves. A shift from iterative learning processes to fully standardized working procedures will occur as roles, requirements and action plans start to form.