NNE teamed up with the customer to conceptually design a district cooling system at the customer site. The aim was to identify and describe the idea, clarify the feasibility and evaluate the concept against environmental and financial profitability.

Customer challenge

The customer wishes to improve overall performance, improve environmental performance and lower re-investments of cooling units at their facility site. To do this, they are considering establishing a district cooling system that will connect the cooling capacity in their current production facilities.

Focus areas of the project include:

- Low energy consumption

- Phase out HFC gasses

- Improve ability to continuously secure lowest possible energy consumption

- Ability to connect and disconnect seamlessly

- Seek proven solutions

Our solution

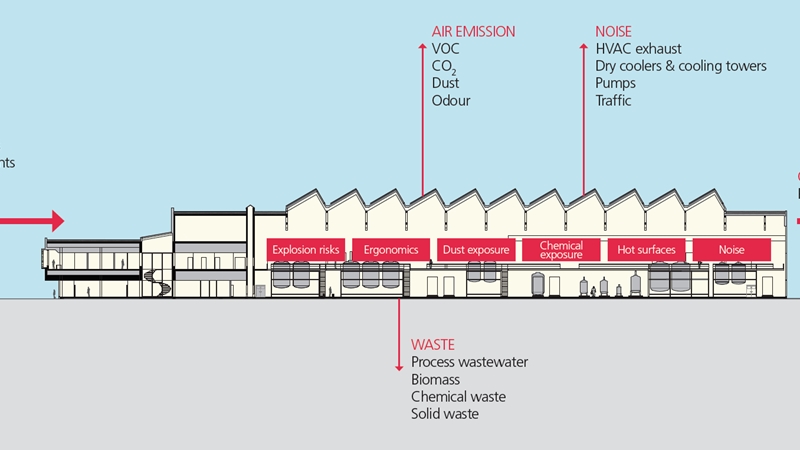

To solve the challenge, NNE gathered a cross-disciplinary team of consultants from decision design, utility and mechanical, infrastructure, health safety and environment, building management system, cost estimating, project management, and operational excellence. Virtual workshops with key customer participants were held over a period of 5 weeks and included inspiration on industry best practices from local universities and utility companies.

The final design solution was created by calculating the capacity need and the cooling capacity available in combination with a consideration of the physical site. Deliveries also included:

- an assessment of the project risks and opportunities

- an operations, procurement, and execution strategy

- a cost and ROI estimation.

Quick facts

Customer

Confidential

Country

Europe

Project duration

5 weeks

Services provided

Conceptual design