When China-based Zhejiang Medicine Co. Ltd. (ZMC) planned the establishment of its first ever biotech manufacturing facility in China, it looked for an engineering partner with deep knowledge within antibody-drug conjugates. NNE proved the right fit and we delivered a fast-track design for ZMC’s new facility monoclonal antibodies and antibody-drug conjugates.

Zhejiang Medicine Co. Ltd. (ZMC) has manufactured and marketed pharmaceutical products to the Chinese market for decades. With an ambition to move into the biotech market, the company partnered with US-based Ambrx for the development and commercialization of a new antibody-drug conjugate (ADC). And with ZMC’s limited experience in biotech production, the company also looked for a strong partner to help establish a new facility for the manufacturing of new product.

Finding the perfect partner

ZMC had a long list of requirements for its engineering partner. Beside expertise in ADC process design, which is still a rather new technology, ZMC wanted someone with experience in isolator filling lines. It also looked for a partner with strong GMP know-how in order to ensure compliance with CFDA, FDA and EMEA regulations as well as local design code.

Zhejiang was not able to find an engineering company in China with the level of ADC expertise, it was looking for. Hence, the company had to look outside the national borders to find the right partner. While many of the vendors that Zhejiang invited to bid offered strong competences within process design, they did not have sufficient experience in facility design.

ZMC decided to go with NNE because of unique combination of expertise within both process and facility design and our track-record of ADC and mAb projects. Coupled with our deep knowledge within global and local regulations, NNE proved the perfect match for ZMC.

A joint effort for project success

The NNE team delivered the conceptual design in 12 weeks. A strong cooperation with ZMC’s project team throughout the conceptual design execution, was pivotal in meeting the fast-track schedule.

“We are very happy with the cooperation between the two sides. The NNE team members demonstrated their experienced, professional competence throughout the conceptual design and delivered on time and budget,” says Zhu Jing Jing, Biological Manager of NovoCodex Biopharmaceuticals, the subsidiary of ZMC. “I hope we can work together in the future” she finishes.

The NNE team members demonstrated their experienced, professional competence throughout the conceptual design and delivered on time and budget.

After completion of the conceptual design, the NNE team handed it over to a local design institute which assumes the execution of following design and engineering phases.

ZMC, however, brought NNE back on board for the qualification and commissioning part, which commenced in early 2018. In preparation to this, the NNE team developed a risk assessment, reviewed user requirement specifications and supported validation for critical process equipment. While our involvement in the intervening project phases is minimal, we are supporting ZMC in some of the more critical process design aspects. As such, we help ZMC to review the user requirement specification for the filling lines, which utilize isolator technology, in order to ensure that the facility is based on global best practices and future-proof equipment.

Single-use for flexibility

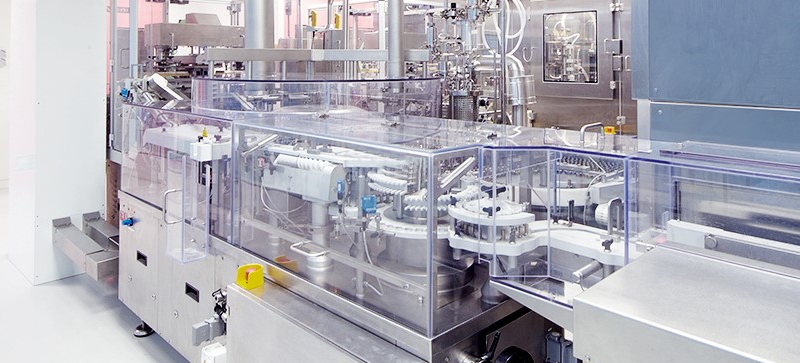

The new biotech facility is located in ZMC’s existing plant in Shaoxing, Zhejiang. It houses a monoclonal antibodies (mAb) manufacturing plant for bulk and fill finish, an antibody-drug conjugate plant, quality control laboratories and a utility center.

The mAb plant is designed for two production lines each with two 2,000L bioreactors. NNE has applied single-use technology both for upstream and downstream. Only the first line, which includes upstream with two 2,000L single-use bioreactors and downstream, will be installed to start with. NNE’s design have reserved the same area/utility consumption for the second line which will installed in a later phase.

The main process in the ADC manufacturing plant includes conjugation and ultrafiltration and diafiltration. It also includes fill finish as well as a vial filling and freezing line.

Quick facts

Customer

Zhejiang Medicine Co. Ltd.

Country

China

Project duration

Nov. 2016 - ongoing

Facility size

26,666 m2

Services provided

Conceptual design, pre-validation support, qualification and commissioning