Using building simulation software to test your pharma facility's performance is not new. But the pharma industry tends to focus on processes and not the building's shape and utilities. Yet when building a digital twin, it is possible to test the effect of all changes - including ventilation, solar shading, lighting, and construction.

In a building, we need a comfortable indoor environment. But this consumes energy. In fact, up to 90% of a typical non-pharma building’s lifecycle carbon emissions are due to heating, cooling, HVAC, lighting, and appliances.

With this in mind, it is difficult to choose which energy optimization initiatives to implement. Which idea is best? How will different initiatives work together? And how much energy can we actually save?

Often, energy savings are calculated using excel documents. But when working with complex interconnected systems such as a pharma facility, we need to look at the bigger picture.

To take an example, when you change the lighting in a building to LED, electricity consumption is significantly reduced. But this also has a knock-on effect for heating and cooling - LED lights emit less heat, so this can reduce the need for cooling or increase the need for more heating. Hence, if you want to optimize a building through multiple initiatives, the total energy savings is not the sum of each of the initiatives, since one may compromise another.

The total energy savings is not the sum of each of the initiatives, since one initiative may compromise another."

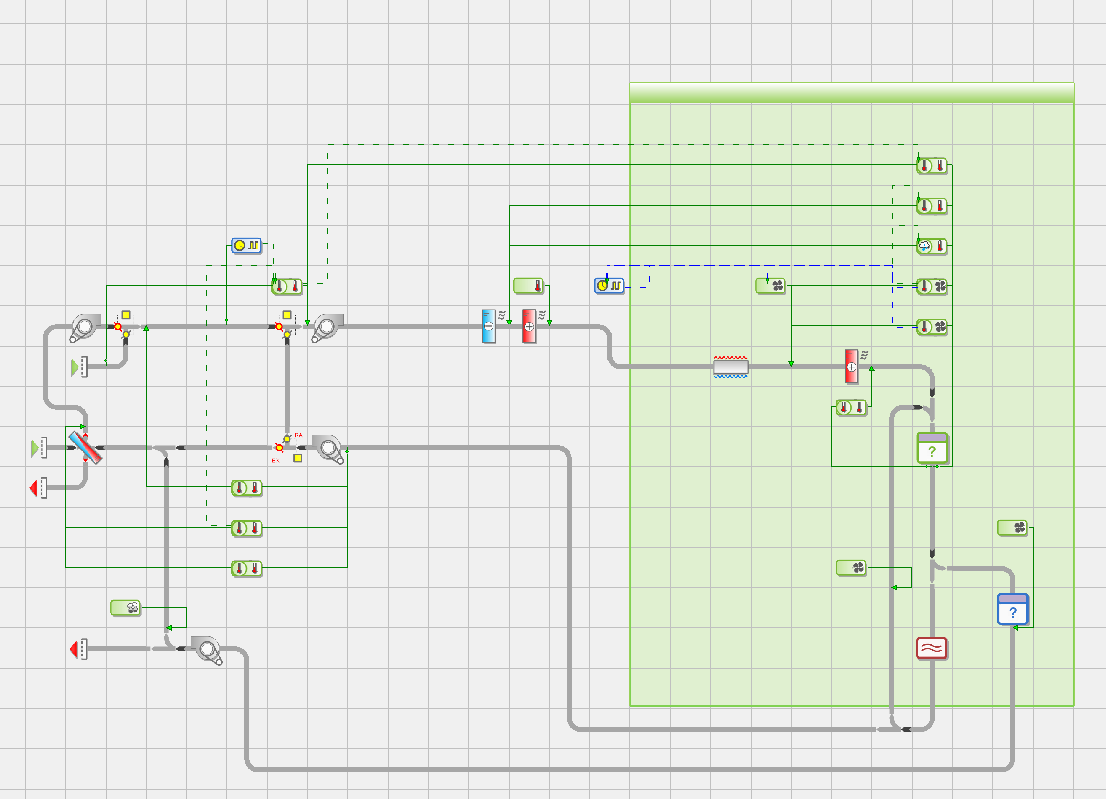

A digital building model is really handy for testing combinations of different ideas to find the best and most economic setup. Advanced building simulation software allows you to specify each energy-consuming system in detail and predict the interconnection of these systems.

The results are generated on a similarly detailed level, allowing designers to investigate the optimal fit. When working with energy optimization in pharma facilities, many different people need to be involved; architects, electrical engineers, HVAC engineers, and utility (clean and black) experts to name a few. Importantly, each initiative must be studied and verified in relation to good manufacturing practice.

Building simulation software in the pharma industry

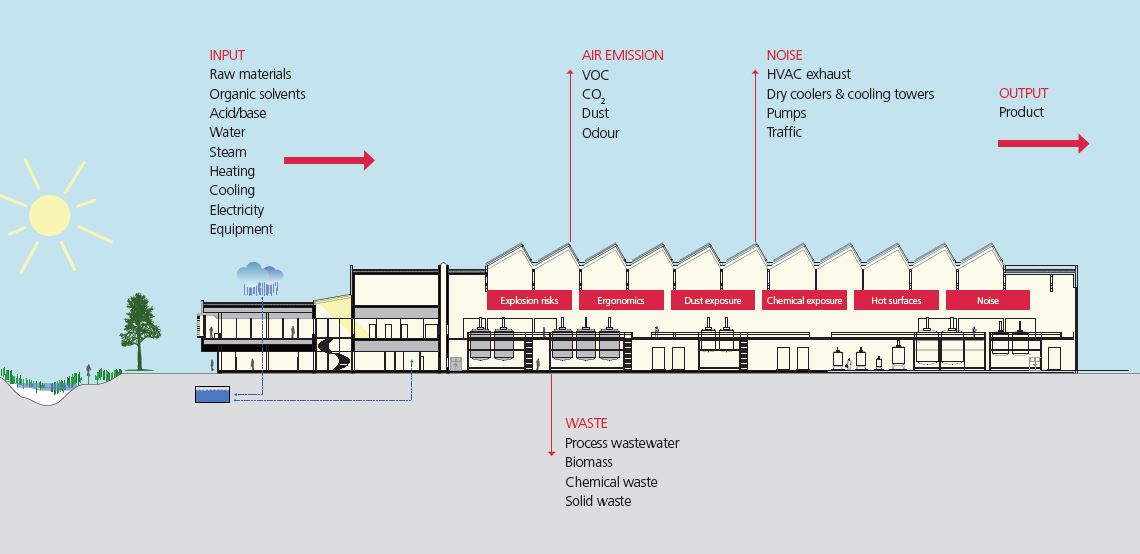

The processes involved in producing a medicinal product are typically very energy-intensive. Hence, the overall benefit of making a facility’s building parameters more efficient (such as construction, window shells, and detailed control of the indoor environment) is marginal compared to the total energy consumption of the facility.

Fortunately, the use of simulation software in the pharma industry is gaining ground, since the tools help us investigate creative solutions across the interface between facility processes and building operations. One example would be reusing wastewater for heating.

Additionally, simulations make it possible to analyze the setback of HVAC systems in classified areas or in areas with a large amount of air exchange. We can investigate the impact on temperature, humidity, and other parameters, without putting the product at risk.

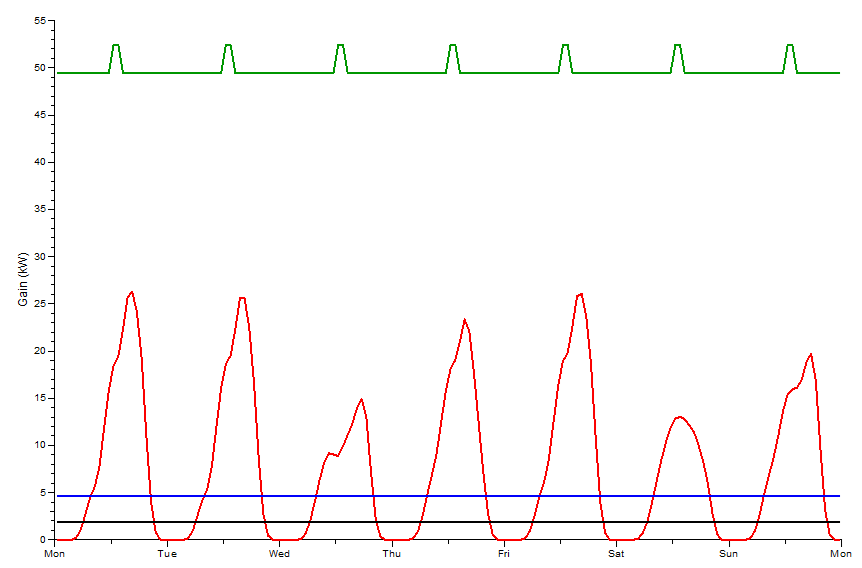

Figure 1: Example of a simulation result showing heat gain in a room in 7 days. The curves are the sun (weather data), appliances and equipment, lighting, and occupants

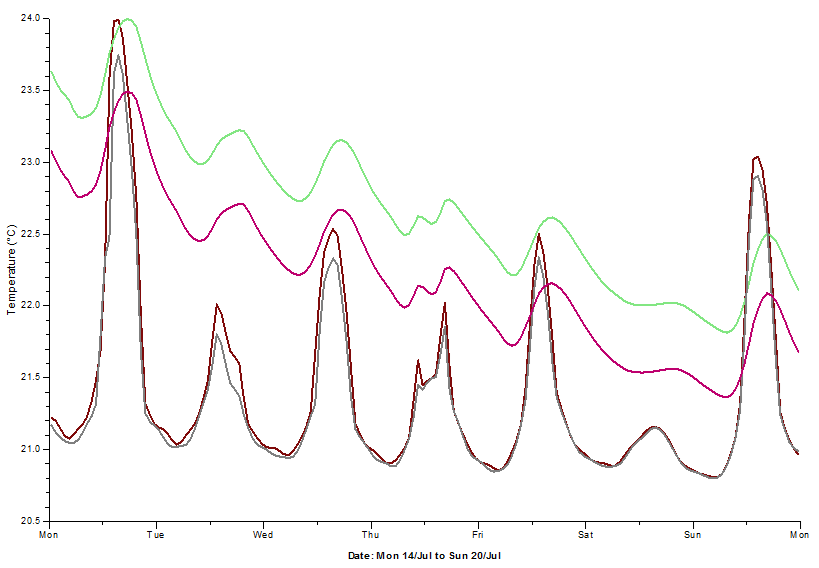

Figure 2: Simulation results showing room temperature in three different HVAC control strategies

Figure 3: Example of a detailed representation of an air handling unit with active and dynamic components

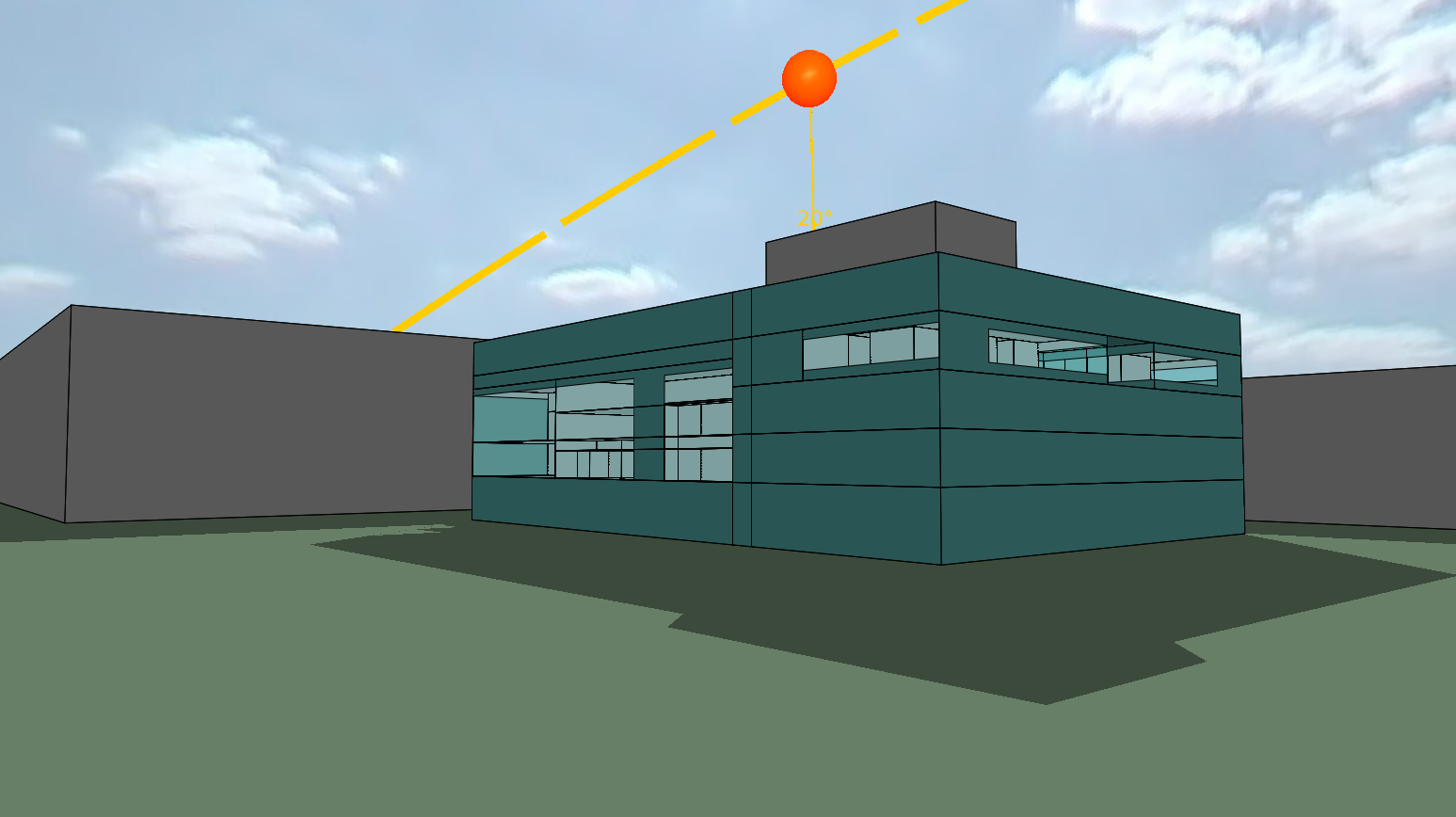

Figure 4: 3D building model placed in a virtual environment

Bridging the gap between predictive measures and real systems – the evolution of the digital twin

Building simulation tools are commonly used during the design phase of a pharma facility project. However, numerous studies have shown that actual building performance often deviates significantly from the predictions observed in building simulations. The gap is typically known as the “performance gap”. The gap occurs when the digital building model lacks precision in predicting uncertainties that buildings are subject to, such as weather cycles, facility usage, occupancy, and system degradation.

In order to account for these uncertainties, digital models must be continuously calibrated with information obtained from the building monitoring system (operational energy loads, metered data) and from sensor recordings (temperature, relative humidity, CO2, and occupancy). This data is then imported into the model as updated profiles for performing new simulations. Continuously doing so ensures the digital twin evolves in parallel with the actual building. This makes it possible, for instance, to produce highly efficient operational and hence energy-optimized plans for HVAC, lighting, and utility systems that are tailored to both the building and user's needs.

|

Building simulation in short To be able to do building simulations, an extensive digital model is needed. At the very least, the model must include:

The model is placed in a virtual environment with geographical weather data, and simulations on energy consumption and/or indoor climate can begin. Compatible software includes B-SIM, IES-VE and IDA ICE. |