When talking about digitalization in the industry, we often hear the phrase "digital twin". But what is a digital twin and what can it be used for? In this TechTalk article, Leif Poulsen gets to grip with this question and offers some examples of how this technology is used in the pharmaceutical manufacturing industry.

A digital twin is a digital model of a physical object in the supply chain. This model is a "mirror image" of a physical object, where functions and properties are represented by digital information.

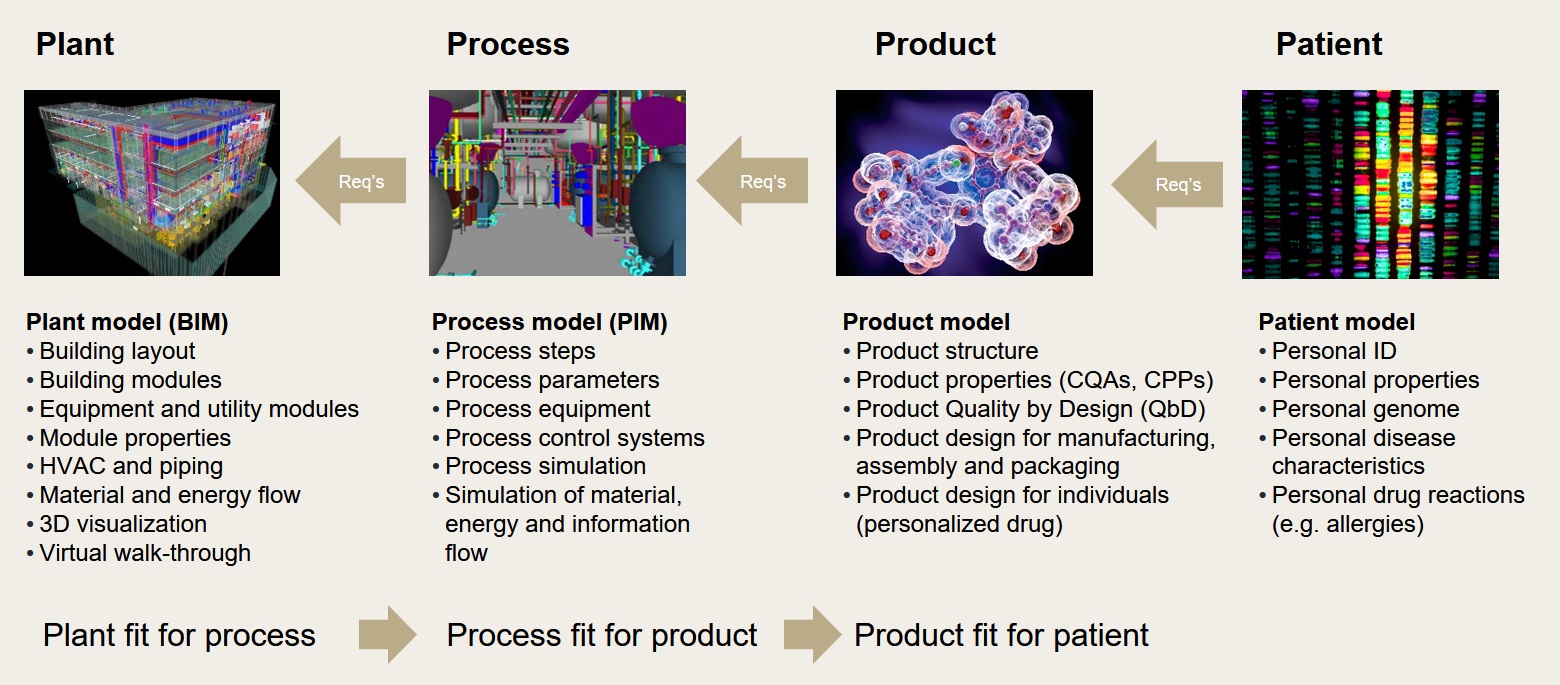

Within pharma manufacturing, we tend to work with digitally modelling the following physical objects:

- The production building

- The production process

- The product itself

- The patient

These are often referred to as the 4-P model, or “digital quadruplets” (detailed above). Digital models of these objects can be used to design and optimize individual physical objects and, if combined, to design and optimize the entire supply chain. So what are the possibilities for digitalization, design and optimization in these 4-P areas?

Digitalization of production buildings

For many years, advanced 3D tools for modelling geometric properties have supported the design of buildings and building elements. Indeed, it is now possible to create very realistic visualizations of a building's interior and even let people take a virtual walk around before it is physically built. This is particularly effective for sales.

However, a 3D model can also be used for many other things, such as ensuring there is space for necessary production and supply systems. During a project, a 3D model is often used by project managers to match deliveries from different suppliers.

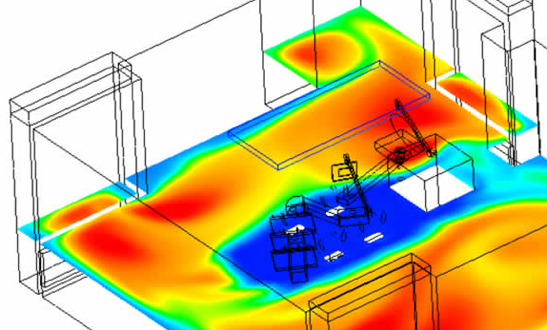

A 3D model can also have features for modelling the building's more dynamic properties – such as modelling the amount of energy consumed under varying production and weather conditions (see fig. 2).

Digitalization of the pharma production process

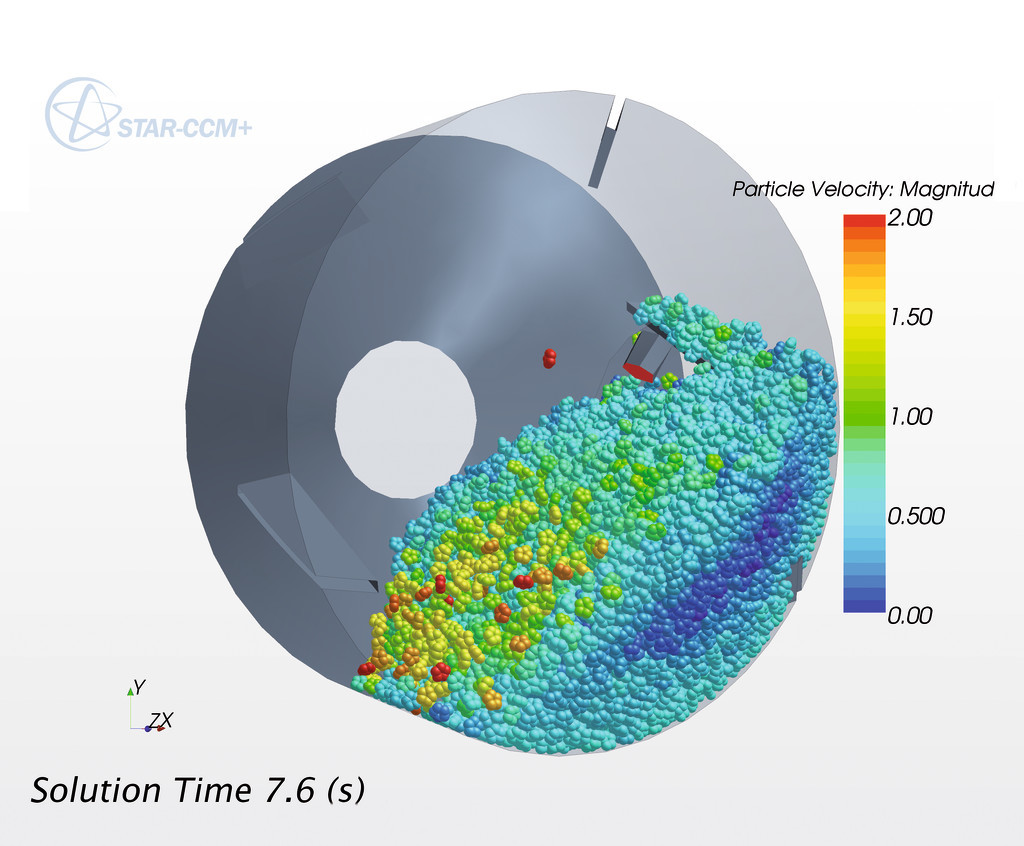

Physical experiments are often used to optimize processes, but digital models can also help find better solutions. These are often based on mathematical or stochastic models (or a combination of the two) and are gradually integrated into the geometric modelling techniques mentioned above.

A good example of this is optimizing the process of mixing different granules for tablet production. In the United States, MIT has developed an advanced mathematical model of a continuous process, where you can estimate how effective a mixing plant is at homogenizing granules as a function of its physical design. This can be visualized using different colours for single particles in the granulate (see fig. 3).

Digitalization of medical products

|

Digital models are increasingly being used to design and optimize products and medical delivery systems, such as insulin pens. New pens are usually designed from a digital platform, and then a large part of the design is reused in many different pen variants. With the help of digital models, it is possible to quickly examine whether a new variant fits into existing production equipment (an example of design for manufacturing). In addition, many newer pens also have electronic functions that can, for example, tell a patient how to use the pen correctly and send information about a treatment program to a doctor or hospital (see fig. 4). |

|

Digitalization of the patient (the customer)

Products across all industries are increasingly manufactured to suit customer needs. This also applies in the pharmaceutical industry, where products are now adapted for smaller patient groups and ultimately the individual patient - also known as personalized medicine. Therefore, it is increasingly important to have a digital model of a patient's medical information so they get the right products and the most effective treatment.

A good example of this is cell therapy, where patients are treated with modified cells from their own body. In these cases it is crucial that digital information taken from analyzing individual patients is channelled efficiently and safely to production equipment. This then produces the personalized drug for the patient – for example, based on the results of a gene analysis (see fig. 5).

Dynamically optimize your supply chain

Pharma manufacturing has been slow to adopt integrated digitalization compared to other industries. Within car and aircraft manufacturing, for example, integrated models are already used to optimize processes and products according to customer needs.

However, there are clearly many benefits of integrating the 4 models briefly described above. By embracing this technology, it is possible to dynamically optimize the entire supply chain - so products are optimized for patient needs, the process is optimized for manufactured products, and facilities are optimized for processes.