Today, many pharma laboratories operate in a manual/semi-automatic way and are still burdened with tedious paper-based documentation. However, frontrunners in the industry have started to digitally transform lab operations to increase efficiency and decrease lead time. The potential benefits of this are huge. Read more to see some examples of these changes and a business strategy for moving forward.

Computer controlled instruments instead of manually operated instruments

To examine some of the examples in these front-runner laboratories, manually operated instruments are now being replaced with computer-controlled instruments. Plans on what to analyze are automatically fed to these instruments, before execution and test results are automatically sent to central systems for documentation or further analysis.

Finally, results can be uploaded to a central data repository where advanced data analytical tools can use artificial intelligence and machine learning for further insight.

Robotics in lab operations

In addition, robotics can be very useful for laboratory operations. Multiple related analytical instruments can be combined in laboratory areas, with robots that transfer samples from one instrument to another. Automated guided vehicles (mobile robots) can also transfer samples between these areas. Samples can then be tracked digitally by using matrix codes or radio-frequency indentification (RFID) chips.

Advanced finite scheduling systems for laboratories

To optimize the utilization of highly automated lab instruments, labs can also take advantage of an advanced finite scheduling system. This

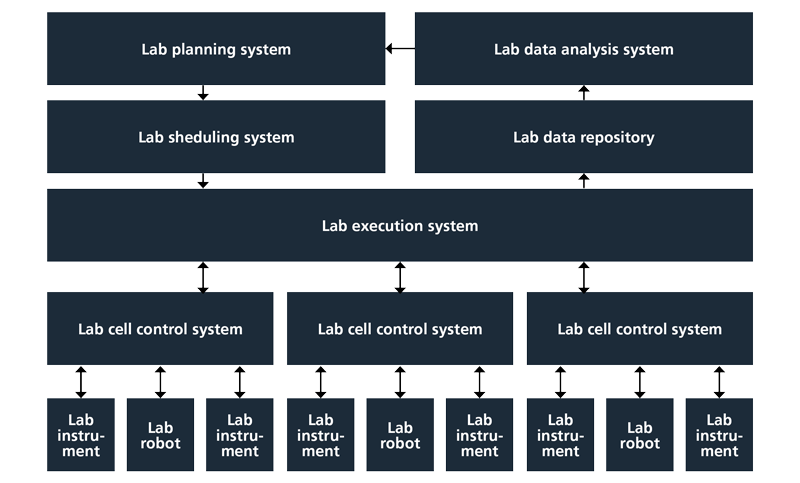

A typical example of a system architecture for advanced digital operation of development labs is shown below:

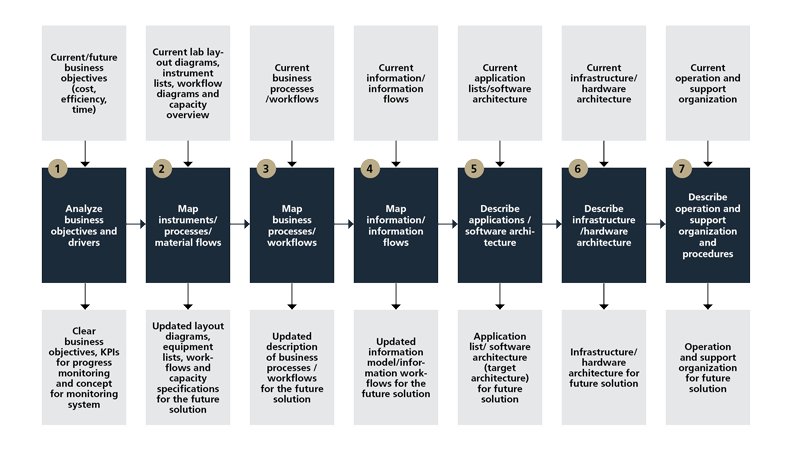

Digital transformation stategy for lab operations

Automated and integrated lab solutions can speed up the launch of products and cut down cost for development/production of products. However, the actual solution must be adapted and aligned with company specific business objectives and strategies.

A digital transformation strategy is therefore vital for lab operation, as outlined in the illustration below.