Fresenius Hemocare CZ needed to revamp its existing production facility for blood bags. The company chose NNE for compliance expertise, and received an added bonus of outstanding team management.

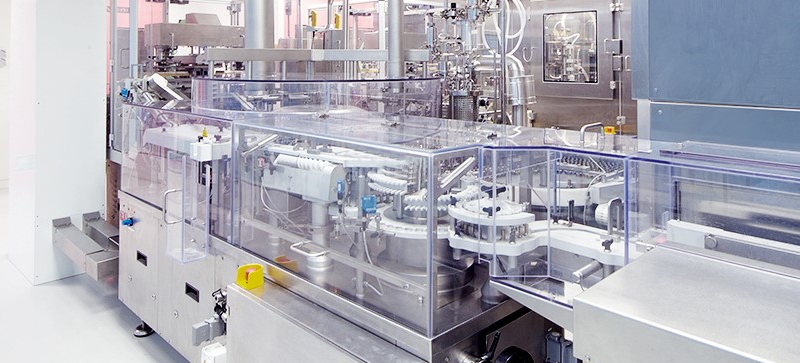

In its revamped facility, Fresenius Hemocare CZ needed to assemble, fill, sterilize and pack blood bags complying with ISO and cGMP requirements.

When NNE completed the conceptual design and process engineering for the facility, Fresenius Hemocare CZ then asked NNE to help with the new HVAC and cleanroom systems. This included overhauling and extending the existing machinery room for HVAC, as well as reinforcing the existing steel structure during the running production – all while meeting a fast-track timeline.

Personal touch helps balance large team

To meet Fresenius Hemocare CZ’s budget, time and quality targets, NNE had to deliver a turnkey solution and execute the project with a joint German and Czech project team. All partner companies and as many as 10 sub-vendors were coordinated and integrated into one team during the execution phase.

The key to a timely and successful outcome was NNE’s daily follow-up, which was based on a structured concept and close communication with all involved parties. Fresenius Hemocare CZ was impressed with NNE’s hands-on approach and attention to detail.