The global pharmaceutical industry is soaring. Many new medicine types and products are starting to emerge, leaving a huge demand for new production capacity. At NNE, this demand for new production capacity is also showcased through a booming pipeline of projects. We asked Project Vice President, Jens Olesen, to highlight three key trends in the shaping of tomorrow's medicine facilities.

Flexible solutions are the way forward

One of the latest trends that significantly impacts how we design facilities – and how we work – is the increasing need for flexibility.

Sometimes, a facility may have to produce a new type of medicine, requiring a different or entirely new production line. An increasing number of facilities we design today are therefore designed to be flexible so that the line can easily be converted to produce a new product. That enables our customers to meet changing market needs.

Agility and flexibility are operating words in the way we execute projects at NNE. We are experts in adjusting our solutions to fit the customer's requirements and delivering what the customer needs, even if that need is unknown when we break ground. We don't practice a zero-error culture. Instead, we encourage creativity and adaptability, and we are not afraid to do things in a new way.

Driving digital development

Digitalization is another major trend, shaping our solutions and ways of working. The way we work is becoming more and more digital and data-driven – and so are the solutions we deliver to our customers.

When we design facilities today, everything is designed in 3D, which enables the customer to move around inside a digital twin of their yet-to-be-build facility. Here, they can review the facility's functionality, i.e., workflows, handling of equipment and material, maintainability of the equipment, and so on.

The next big thing in the digitalization scene is data-driven engineering. Designing medicine facilities is complex and requires close interaction between different players, e.g., engineering disciplines, architects, suppliers, contractors, and customers. We connect data and information from all project stakeholders with data-driven engineering, creating a more automated information flow. This ensures better alignment and higher efficiency in the work that is done. Much of the data can be put into the 3D model, which then turns from "just" a visual tool that supports the design phase into a valuable source of information throughout the facility's lifecycle.

Data-driven engineering is still new in the pharma industry, so it's not "standardized" yet, but no doubt that it will be in the future. The digitalization journey – both for NNE and for our customers – is a never-ending one.

Helping pharma go greener

The sustainability wave has also hit the pharma industry, and our customers are increasingly focused on bringing down their CO2 footprint.

NNE has a significant impact on the green transition in society through our design of pharma facilities which will produce medicine far into the future. The pharma industry is an emission intensive, expanding market. Therefore, we have a responsibility to do everything we can to deliver sustainable projects by supporting our customers to make the right decisions.

We help our customers to understand the environmental impact of their projects by quantifying the future carbon footprint and consumption of resources such as energy, water, and chemicals. And during the design phase of a pharma facility, we identify and implement innovative solutions to reduce the impact to a minimum.

We work with sustainability on many levels, from minor rebuilds to new greenfield facilities and industrial symbiosis. Our focus is on enabling circularity by re-using resources to the greatest extent possible, and our ambition is to reach a "closed loop" production. Many of the sustainable design solutions we build focus on reducing water consumption. The production of medicine requires a lot of water, but water can be a scarce resource, so it is an area with great potential to minimize environmental impact.

In one of our current projects, we're actually able to document that we have reduced water consumption by around 65% compared to a comparable facility by, e.g., recycling process liquids and redesigning the process setup.

Want to be a part of shaping the future of pharma engineering?

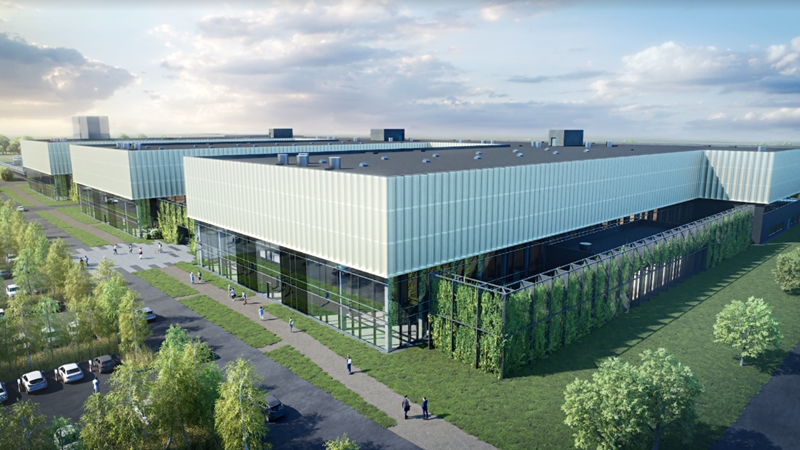

In the next few years, NNE will build some of the biggest and most advanced pharma facilities in the world, setting new standards for sustainability, digital solutions and innovation. If you join us on this exciting journey, we not only promise you complex challenges and a job with purpose, but also great development opportunities and fantastic colleagues.

If that sounds intriguing to you, we urge you to check out our open positions. Perhaps we’re a match?

We asked four of our colleagues what they like most about working at NNE. Watch the video to find out what they said.