Distribution systems for gas, steam and water are quite simple – so many assume designing their automation should be quick and easy. Yet considering how long these systems run, underestimating the value of a careful design can be very expensive long term. In this TechTalk article, we walk you through some potential problems and tips for making a strong automation design.

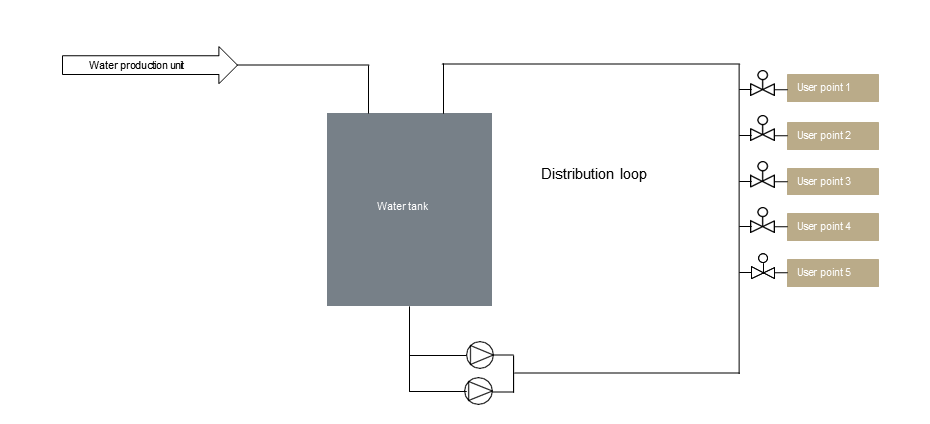

In principle, distribution systems for utilities such as gas, steam and water are relatively straightforward. A production system sends out the utility medium to user points through pipes in a star or a loop configuration, where a valve provides access to it when needed.

Because of this, pharma manufacturers often assume setting up their automation should be a simple task. Yet experience shows underestimating the value of a carefully designed distribution system can be very expensive long term. These systems run for decades, generating substantial costs for testing and maintenance, and any changes to requirements and system configuration is costly. It is worthwhile, therefore, to spend some time and effort on a strong design.

Basic principles to get started with the design

Typically, a distribution system in pharma manufacturing runs continuously. So even though “batch” reports are regularly made during operation, the system is not a batch system. Nevertheless, it is important to keep in mind that the principles of the S88 standard for batch processes are still relevant for structuring an automation solution for these systems. Product tracing requirements may make it necessary to define batches by separating the media supply into distinct time periods. Some control systems used for implementation may require the same approach.

So how can you go about the design? To take a closer look at the physical model, a basic principle for structuring plant equipment into units is that a unit can never hold more than one batch. However,if batches are not defined for the distribution system, you could apply the following principles:

- Parts that are closely functionally connected should be placed in the same unit

- Parts that are not closely functionally connected should be placed in different units

When presented like this it seems obvious. Yet violations still happen. For example, if a tank and the distribution loop for a water system are placed in separate units, possibly due to a special system configuration, this means the operation of the two units need to be coordinated. Ultimately, a poor definition of units makes the automation solution more complex.

Tips for equipment module design

Control of components (like valves and pumps) is usually allocated to equipment modules. A distribution system is no exception. However, a state matrix that is customary for defining the component state for each equipment module state is less useful. This is because the valve for a single user point should operate independently of all other user point valves, provided certain overall conditions are fulfilled. You can set these equipment module conditions by changing its state e.g. from “idle” where all user point valves are closed, to “available” where valves can be operated on request.

The control for a single user point can be handled with continuous logic within the equipment module. Beyond operating the user point valve, such logic may include communication with the system connected to the user point and enabling/disabling alarms specifically related to it.

In fact, you can generally reduce system complexity by using continuous logic in equipment modules – so higher-level controls can concentrate on coordination, scheduling and use of resources. Out of concern for system complexity, it is also a good idea to allocate components to equipment modules in a way that the procedural level sees a simple interface where components are grouped together logically.

Tips for designing procedural models

The procedural model should comprise solutions for a variety of requirements for a specific system. These include:

Start/stop

For a simple distribution system, the start-up routine is to download recipe parameters, primarily for alarm limits, before the equipment modules are set to operate. Less simple systems, however, may need a sequence of actions for filling up pipes and tanks, starting circulation, and heating or cooling equipment. Equivalently, a shut-down procedure may be more or less complex, ranging from simply turning off the power to actually emptying the equipment.

Monitoring

During operation, you may need to monitor parameters that affect all user points, such as pressure, temperature and conductivity. You may need to also record minimum and maximum values for reporting purposes. Alarms and warnings may be issued, and this is usually followed up by stopping supply to the user points. In this case, a well-structured design pays off, as stopping and resuming supply only includes going from one step to another in a sequence that controls equipment module states.

Priority

When production system capacity is less than the maximum user point consumption, you may need a priority scheme. This means certain user points are made higher priority for servicing, based on one or more critical parameters for the supply (e.g. pressure, temperature or level in a tank). The procedural model should track these parameters and decide whether more or less user points should be able to request service. Any conclusions should be communicated to the equipment modules so their continuous logic can act accordingly.

Sanitization

Utility distribution systems, such as water, need regular sanitization e.g. by circulating water at a high temperature for a period of time. User points cannot be serviced during sanitization, so it is important to set any equipment modules handling them to a state disabling that. The procedure for sanitization and switching between that and distribution is ordinary sequential processing.

Servicing

Most utility distribution systems operate continuously, so servicing can be a challenge. To help with this, it can be useful to include ways to enable various service modes as an alternative to a complete shutdown. For example, one mode could be to disable specific users or specific user groups. Another could be to exclude the use of measurements during service of instruments, including calibration.

Most importantly for the structure is that it is possible to separate concerns. You can achieve this by including a strong internal coherence for structural elements (e.g. phases and equipment modules) and a weak coupling between them. An equipment module should do as much as it can related to equipment control, and have the authority to do so within well-defined conditions. Such conditions should be established by elements of the procedural model (phases, operations, unit procedures) so you can meet the requirements for operating the distribution system.

Overall, the best structure for your automation system for utility distribution depends on its physical configuration (piping and instrumentation), the medium being distributed, and on specific user requirements. Thus, it is worth investing in automation design and deciding what to emphasize during the design process to save considerable time and money further down the line.