Automation and IT strategy

for pharma manufacturing

Need help balancing cost, flexibility, quality and GMP compliance in your pharma facility? Our experienced strategic consultants can find the right automation and IT solution for your challenge.

Get in touch, let us know your issue and we'll get the right team on the case.

Why choose NNE?

NNE has a long track record of developing and implementing advanced automation and IT solutions for pharma and biotech. We’ve helped customers with numerous systems, from simple barcode tracking solutions to completely paperless production facilities.

Browse a small selection of our strategic services below, or contact us above to find out exactly how we can help you.

Need a strategy consultation?

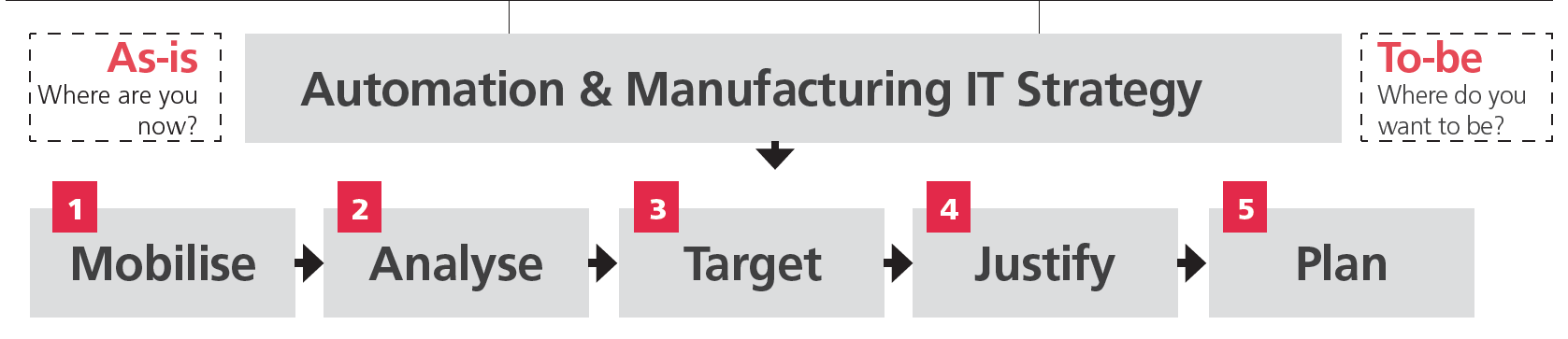

REACH PHARMA 4.0 WITH A STRONG AUTOMATION AND IT STRATEGY

An Automation and IT Strategy is essential to maximize benefits and make the right decisions. It ensures investments are driven by business goals (and not technology) and aligns efforts with a future target. Knowing where you are and where you need to be can also significantly reduce costs, as it prevents you from investing in disparate solutions along the way.

WHEN TO UPDATE YOUR AUTOMATION AND IT STRATEGY

An Automation and IT strategy should always be in force. But it also needs to be updated with periodical revisions when:

• Satisfaction with existing systems and their maintenance is low.

• Your business goals or manufacturing processes change.

• When you face significant replacements or upgrades.

• When you want to coordinate the use of systems across several plants, sites or divisions.

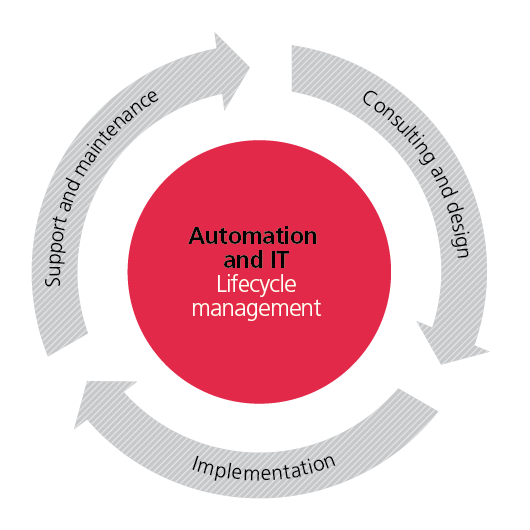

Reduce risk of failure with lifecycle management

IS YOUR FACILITY AT RISK? FIND OUT WITH NNE’S ADVANCED SITE ASSESSMENT

To help future-proof your facility and mitigate risk, our specialists offer an automation assessment of your equipment, production line or even the entire site – and a report on your production lifecycle, including:

• Automation compliance status

• Lifecycle status on equipment

• Industrial security and threat landscape

• Estimation of production failure risks

• Level of maintenance of production

• Migration recommendations plants, sites or divisions.