The fourth industrial revolution is upon us and emerging technologies like robotics dominate the manufacturing industry. So is your pharma facility ready for robotic solutions? Find out how to pave the way for robots and other emerging technologies in pharma 4.0.

Robotic technology has developed dramatically over the last decade and many industries from the automotive world to electronics have embraced it with open arms. Sales of robots and collaborative robots, or ‘cobots,’ are expected to increase steadily and, in fact, the worldwide sale of industrial robots set a new record in 2015 - 254,000 units were sold, a 15% increase from 2014[1]. This trend shows no signs of slowing down.

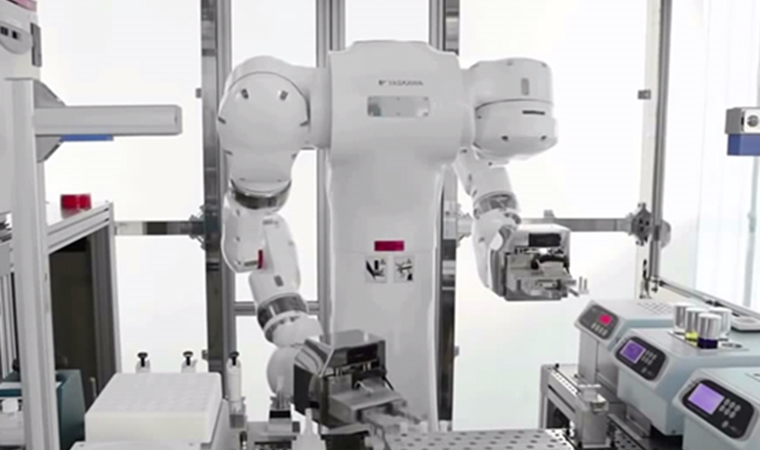

The healthcare industry is now following suit. For example, robotics are now used to compound drugs, which helps to improve operator safety, quality and cost. But in order to fully embrace this pharma 4.0 concept, pharma manufacturers should ask themselves the following questions: what can robotics do for our manufacturing facility? Are we ready to implement robotics directly? And if not, how can we prepare?

Having robots perform error prone tasks such as aseptic fill finish, where human error can ruin an expensive batch of drugs, is good. However, having robots perform these tasks while integrated systems track quality and offer real-time visibility is better.

Beyond robotics – learn from industry 4.0 to optimize pharma 4.0

When it comes to robotics, it pays to think big. So when you envision using robotics, consider thinking one step ahead. While robotic solutions are revolutionizing manufacturing, it is the combination of robots with other technologies that can tip business cases from solely "efficient" to a true symphony of improvements for the operator environment, quality and productivity.

The dominant automation trend known as ‘Industry 4.0,’ or ‘The fourth industrial revolution,’ promotes this union of emerging technologies to maximize a harmonious production. Industry 4.0 embraces the integration of four primary advantages:

- Interoperability with machines, devices, sensors and people connecting via Internet of Things (IoT)

- Decentralized solutions allowing cyber physical systems to make decisions on their own and operate autonomously

- Information transparency wherein information systems create a virtual twin of the physical plant

- Technical assistance to support humans in solving urgent problems by aggregating and presenting information where the problems are

Having robots perform error prone tasks such as aseptic fill finish, where human error can ruin an expensive batch of drugs, is good. However, having robots perform these tasks while integrated systems track quality and offer real-time visibility is better.

The fusion of emerging technologies will allow you to simulate production, optimize and test changes, and train operators before any physical action takes place. Virtual studies will save manufacturers valuable time and money while simultaneously offering a safer product. Furthermore, technologically advanced production will satisfy future operators, who will be fewer in number and more specialized than operators of the past.

Are you ready? Making a robotics strategy.

Robots, simulations, cloud computing, cyber security, augmented reality – all of these technologies sound great. But how practical are they to implement? Is your facility ready to start this process?

To assess the situation and create a roadmap to exploit Industry 4.0 technologies, you should lean on a robust automation and IT manufacturing strategy that focuses on the entire business, the enterprise architecture, and direct change.

Plus, we cannot emphasise enough the importance of aligning with top management, exploiting strategic opportunities across the company and influencing capital plans. In fact, manoeuvring this complex relationship is only possible with strategy. This strategy should target your processes, information, applications, and the people with necessary support.

When your organization has a handle on these aspects, you can make intelligent decisions regarding robotics and other emerging technologies. This will improve impact and integration.

In short, manufacturers want to work smarter, not harder. With intelligent, real-time orchestration and optimization of business alongside physical and digital processes within factories and the entire value chain, this can be possible. But to foster smart manufacturing, make sure you have a complete picture of the entire organization and the way robotics and other technologies can support it.

[1] "Industrial Robots for Pharmaceutical & Cosmetics Industry: Global Market 2016-2022." Research and Markets, Apr. 2017.