NNE is providing end-to-end engineering services and automation support to establish a fermentation and recovery multiline with optimized product change-over, high level of automation and sustainable solutions.

Customer challenge

Our customer needed to quickly establish increased capacity for already commercialized products and needs phase 3 launch capacity to accommodate a strong pipeline of new products.

This project will support new capacity from 2024 with the aim to establish the most innovative and flexible facility. Focus will be to establish a multi-line with optimized change-over between products, a high level of automation to keep constant manning and integrated sustainable solutions.

The customer turned to NNE to help them meet its ambitions based on our track-record in similar projects and for our know-how within manufacturing technology trends and manufacturing intelligence.

Our solution

Through 6 weeks of concept development, a joint NNE and customer team investigated several layout alternatives in the customer’s existing building in order to find space effective solutions. After deciding on one, we further developed the design during an accelerated workshop-based conceptual design of eight weeks.

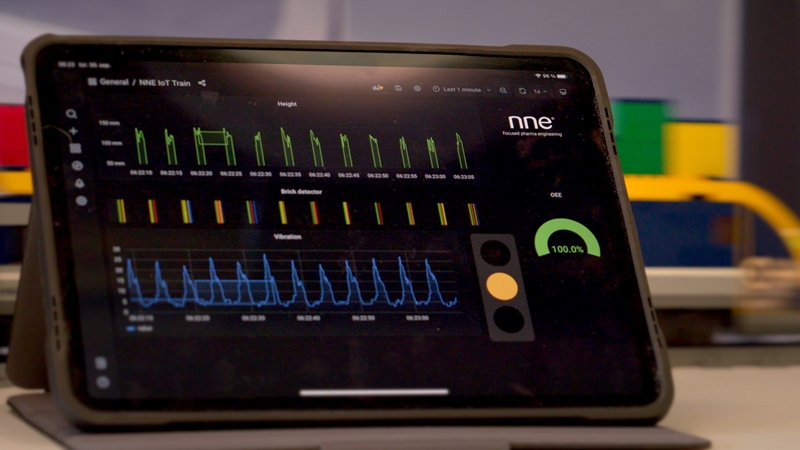

The solution entails revamping an existing fermenter line related support functions to establish simultaneous production in all fermenters with high flexibility for up to 3 simultaneous products. The vision for the new recovery facility is to become a fully automated “lights-out” facility with minimum manning requirements and high area efficiency.

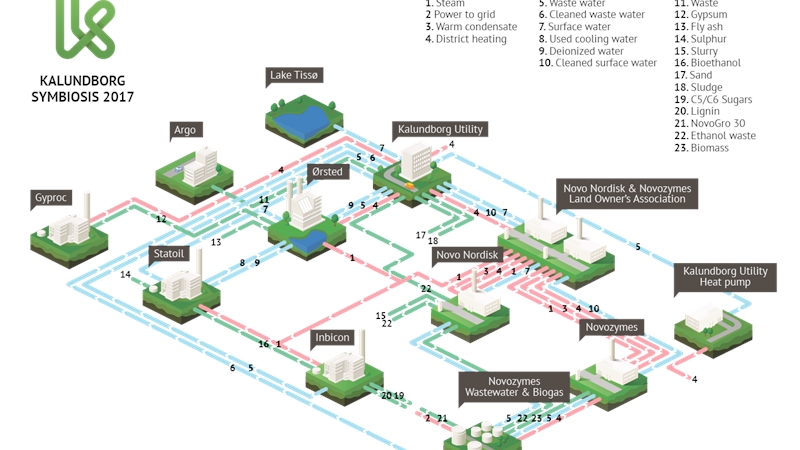

We have achieved major savings in water consumption by:

- Optimizing cleaning-in-place processes

- Reconfiguring process module setup

- Recycling process liquids

Fact box

Customer

Confidential

Region

Europe

Project duration

Apr. 2020 – ongoing (expected 2024)

Services provided

Conceptual design, basic design, EPCMV, automation